The modern pharmaceutical industry faces two key factors which will dictate the course it takes into the future. The world’s aging population means growing patient need and a higher demand for medicines. On the other hand, this ever-increasing demand means the ever-expanding production of therapies and, if left unchecked, the environment will pick up the cost.

That’s why the modern industry must ensure new therapies are produced sustainably, to meet global patient needs without compromising future generations, balancing social, environmental, and economic needs. This presentation covers the sustainable futures vision of the ACS Green Chemistry Institute Pharmaceutical Roundtable: benchmarking different approaches to sustainable industrial peptide manufacturing challenges.

Martin Kenworthy, Associate Principal Scientist at AstraZeneca, delivered this presentation on behalf of the peptide sub-team of the ACS Green Chemistry Institute Pharmaceutical Roundtable, focusing on sustainable peptide manufacturing. Kenworthy outlined that green chemistry and engineering metrics, such as process mass intensity (PMI), are crucial for driving sustainable practices in pharmaceutical manufacturing.

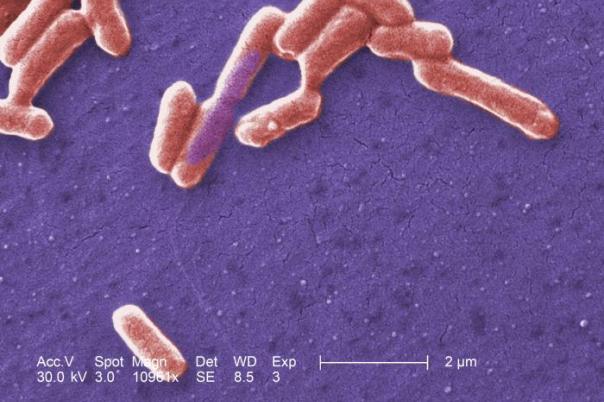

Small molecules are produced through multi-step processes, with solvents and water being major contributors to waste, and PMI benchmarking showing a reduction in PMI through development phases. Oligonucleotides are synthesised using solid-supported resins, with PMI benchmarking showing an average PMI of 4299, and water being the predominant waste. Biologics are produced using fermentation, with water representing 94% of the mass input, making the process inherently more sustainable.

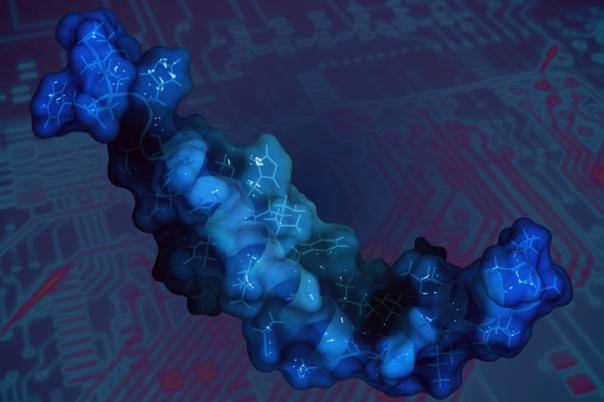

Then Kenworthy discussed the challenges with peptide manufacturing. These include poor atom economy, toxic solvents like DMF, and high PMI values. Alternative methods like fragment-based synthesis and liquid phase synthesis are being explored to address these problems in synthesis. PMI benchmarking for peptides shows higher PMI values compared to other drug modalities, with solid phase synthesis being the predominant technology used.

Future efforts will focus on more detailed life cycle assessments, including carbon footprint and material toxicity, and improving manufacturing efficiency and sustainability.