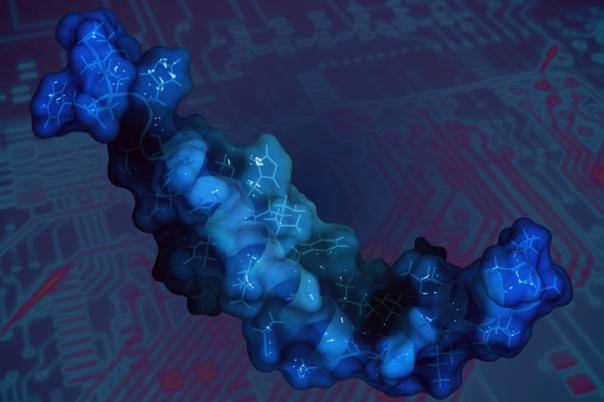

Almac is a CDMO focused on chemical and analytical development for small molecules and peptides. Steven McIntyre, Peptide Process Development at Almac, stated that sustainable peptide manufacturing has seen significant progress but there’s still a long way to go. Almac has created a toolkit to analyse peptide structures, based on thousands of peptides manufactured in the company’s lab. Peptides are typically isolated by lyophilisation after concentration; however, McIntyre is exploring crystallisation and precipitation as alternatives for certain peptides.

Sustainable peptide manufacturing has many challenges. McIntyre identified developing greener processes for peptide API as a critical unmet need. At Almac, greenness is measured using process mass intensity (PMI), a metric indicating how much raw material is needed to produce one kilogram of product. A high PMI correlates with higher CO2 emissions and water usage. Replacing toxic solvents like DMF with greener alternatives like binary solvent systems derived from renewable feedstocks is also a feasible option to promote sustainable chemistry. Unfortunately, no single solvent could fully replace DMF.

McIntyre pointed out the key issue in solid-phase synthesis: “Solid-phase synthesis uses protected amino acids, resulting in significant waste; roughly 75% of the amino acid building block is waste.” The more complex the structure of the peptide, the higher the PMI. Almac’s semi-synthetic cyclic peptide has a PMI of 2300, which is manufactured in solution to conduct a solution-step synthesis and then purification. The team identified that the majority of waste was produced from purification. Although continuous chromatography is an effective way to reduce buffers and increase yields, McIntyre adopted a different approach. He scrutinized purification steps, increasing loading and optimising chromatography by minimising dead-time to reduce PMI by about 20%.

McIntyre expanded on Almac’s extraordinary result when crystallizing their semi-synthetic cyclic peptide: “We could crystallise this cyclic peptide in amorphous form, and it offered a key impurity uplift. By switching isolation techniques, we reduced PMI from 2300 to 630.” Building on this, the team decided to apply their crystallisation technique to a linear peptide. This research is still in its infancy, but early estimates show significant PMI reductions.

In a nutshell, McIntyre illustrated that there's momentum in making peptide chemistry more sustainable. Avoiding chromatography and replacing it with crystallization had a huge impact on process sustainability. However, fundamental issues in peptide chemistry are still present, specifically amide bond formation, which is a big contributor to waste.