Key Takeaways

- MIT developed a faster, cheaper method for purifying AAVs in gene therapy manufacturing.

- Traditional methods waste time and money by producing many empty capsids.

- The new crystallization process is about 10 times quicker than chromatography.

- This method could cut gene therapy drug costs by 5–10 times.

- MIT has applied for a patent and is seeking pharma partners.

Scientists at MIT have developed a new, more efficient method of capsid separation during the gene therapy manufacturing process, potentially reducing costs.

Despite their therapeutic potential, gene therapies are often marred by the high cost of manufacturing that comes with the modality. This high cost can limit their availability for the patients that need them. The new method, described in a paper published in ACS Nano, potentially leading to a reduction in costs and an increase in availability of gene therapies.

Sorting the wheat from the chaff

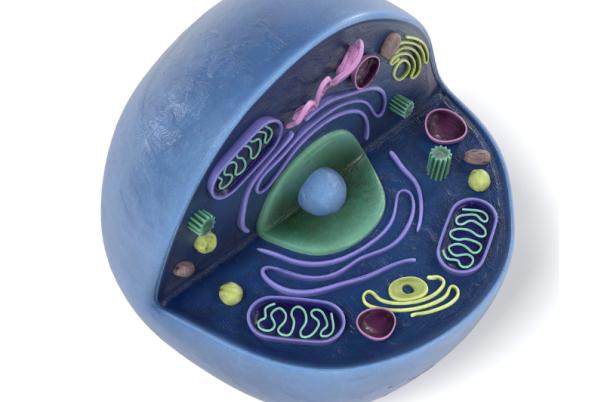

About 60% of global gene therapy clinical trials use adeno-associated viruses (AAV) to carry the therapeutic payload. It’s a great way to deliver genetic material, however the traditional method of gene therapy manufacturing produces a large number of empty capsids in the process.

This can produce yields where only 10% of the produce is viable drug product. Purification – separating the wheat from the chaff – is laborious, can slow down the production process, and drive up costs, especially when scaling up to larger manufacturing operations.

MIT say that this separation can account for almost 70% of gene therapy manufacturing costs, which is why a team at their Department of Chemical Engineering and Centre for Biomedical Innovation, set out to improve this process.

The new method

Usually, chromatography is relied upon for AAV gene-therapy purification. However, the team led by MIT Research Scientist Vivekananda Bal, instead decided to try a crystallisation method instead – a purification process usually reserved for small molecules and never-before-used for capsids.

“[Crystallisation’s] operating time is low, and the product loss is also very low, and the purity achieved is very, very high because of the high selectivity,” said Bal in an MIT news story.

“The time required for purification using the crystallization method is around four hours, compared to that required for the chromatography method, which is about 37 to 40 hours,” he continued.

“So basically, it is about 10 times more effective in terms of operating time.” This novel method will reduce the cost of gene therapy drugs by five to 10 times, he says.

Patent pending

Now the method has experimentally proven effective, the team are looking toward adapting it to large-scales pharmaceutical manufacturing. As such, the team have applied for a patent for the technology and are already talking to multiple potential pharma partners about trialling and later commercialising the system.